Great Quality.timely delivery,favorable price ..

Welcome To The Youjiu magnet wire

What enameled wire we can supply

- Polyester enameled copper wire (PEW)

- Polyurethane enameled copper wire (UEW)

- Direct welding modified polyurethane enameled copper wire (SEIW)

- Polyester imide enameled copper wire (EIW)

- Imidate outer skin modified polyester enameled copper wire (EAIW)

- Polyurethane Enameled Copper Wire (AIW)

- Self-melting enameled copper wire (R * -SB)

alidjie@aluew.com

alidjie@gmail.com

Our Enameled wire Advantages

Youjiu enameled wire supply

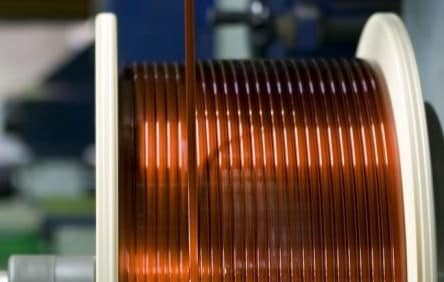

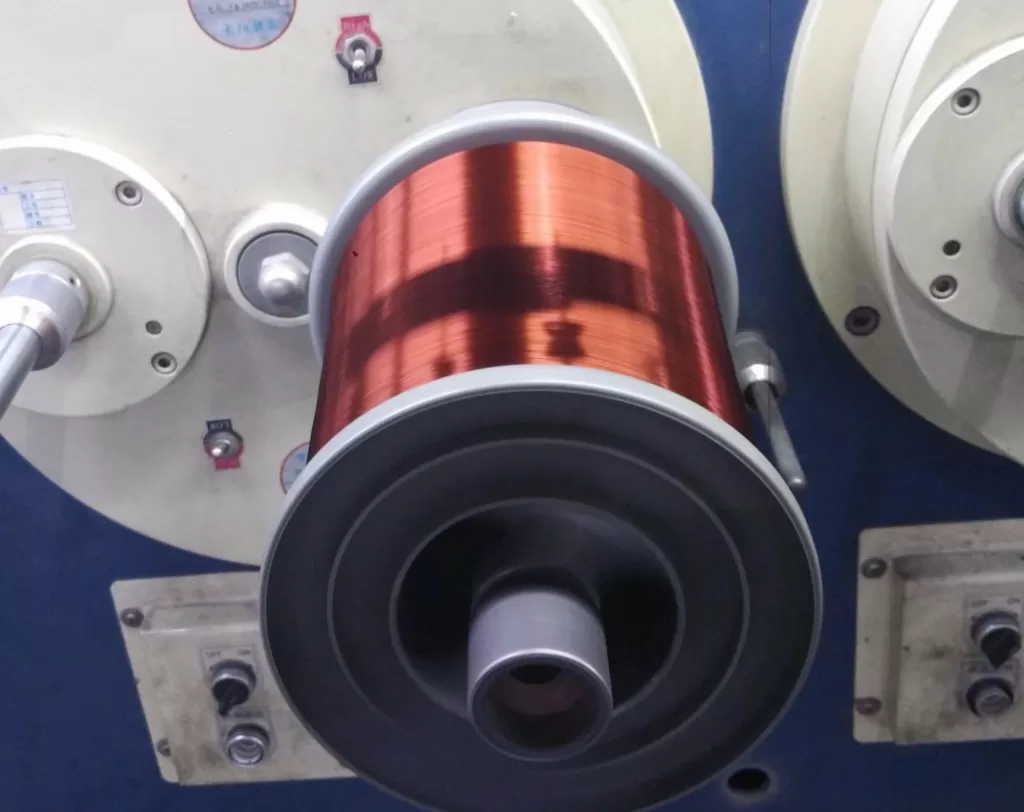

Enameled Copper Wire (Round or Flat)

Enameled Aluminum Round Wire

Standard: SWG / AWG

Temperature: 155℃ 180℃ 200℃ 220℃

Aluminum Wire 0.15mm – 5.00mm

MOQ: 500kgs/size

Size: Copper wire 0.035mm – 6.00mm

Youjiu magnet wire supply high quality Enameled Copper Round Wire, Enameled Copper Flat Wire and Enameled Aluminum Wire

quality standard

Strict implementation of IEC, NEMA, JIS standards, meeting China's environmental requirements can ensure uninterrupted production. Stable operator makes the quality of the product more stable.

long history

Youjiu Enameled Wire,start from 2009, has more than 10 years of experience for deal with enameled wire and control two factory for production Enameled Copper Wire and Enameled Aluminum Wire

No MOQ

All use advanced production equipment, No MOQ, and will be delivered on time.

Inspection

The enameled wire will pass 7 inspection procedures to ensure product quality before the finished product is put into storage.

Mold painting

n order to meet the customer's requirements for the quality of the enameled wire, our painting equipment adopts the method of mold painting, which makes the painting of each pass uniform and excellent.

raw material

Our enameled wire insulation paint will use the best ELANTAS paint and high quality copper & aluminum rod supplier with a purity of 99.9%.

Get your free consultation

Add a line that tells users how easily they can get in touch with you.

Enameled Wire quality control

Quality Control

1.Raw material inspection

High-quality copper or aluminum rod which is under strict standard are extruded and drawn to different suitable dimension by dies machines.

2.Drawing inspection

The high quality and reliability of insulated conductors is dependent not only on the production process, but also on the choice of raw materials.

3.Semi-finished production inspection

Before being coated, the conductor, copper or aluminium is reduced in dimension through drawing (round wire) or flattening (rectangular wire).

4.Finished product inspection

Assured quality of winding wire is first and foremost and cannot be compromised.YOUJIU uses accepted IEC Standards as the minimum measure of quality.

5.Packing & Marking inspection

Production is integrated with an audited Quality Control system supported by a trained technical team and fully equipped laboratory facilities.

6.Up to 13 test items

The most decisive way to test the magnet wire enamel is in its end use in a motor, transformer or coil. Our company has a complete packaging system, there are standard carton, pallet packaging, labels are divided into axle labels and box labels, can be traced back through axle labels, which day? Which stove? Which operator produces it? Which QC inspector inspects?

Our enameled wire use for

We product Enameled Copper Wire & Enameled Aluminum wire use for

- Transformer

- Motor

- Auotmobile Motor

- Magnetizing Coil

enameled copper flat wire

Enameled aluminum wire

Shiqiu Qiu

Quality Engineer

Engaged in quality control of enameled wire production for more than 15 years

I guarantee the quality of your order

Alid Jie

Sales Manager

We have been engaged in export trade for more than 20 years. Joined the company in 2010 and started to set up an export business team to develop the international market.

I provide customers with the most cost-effective copper enameled wire and aluminum enameled wire, you just need to tell me your requirements